Non-Destructive Evaluation Testing (NDE)

The Nondestructive Evaluation (NDE) Laboratory offers traditional and novel NDE services and related engineering support to address custom challenges for a variety of customers, including NASA, the U.S. Air Force, contractors at KSC, the Cape Canaveral Air Force Station and Patrick Air Force Base, and others.

NDE services are performed in the laboratory and in situ to evaluate the quality and integrity of components, systems and structures related to facilities, ground support equipment, payloads and flight vehicles. NDE services are performed by certified personnel in accordance with NASA or contractor specifications or industry standards such as those of the American Society for Testing Materials, American Welding Society and the American Society of Mechanical Engineers.

Capabilities / Services

- ASNT and NASA STD-410 Level I, II, and III certifications

- NDE methods include:

- Visual inspection – remote inspections using bore scopes and fiber-optic systems, AWS certified weld inspection

- Magnetic particle inspection – visible and fluorescent particles, including dry and wet methods

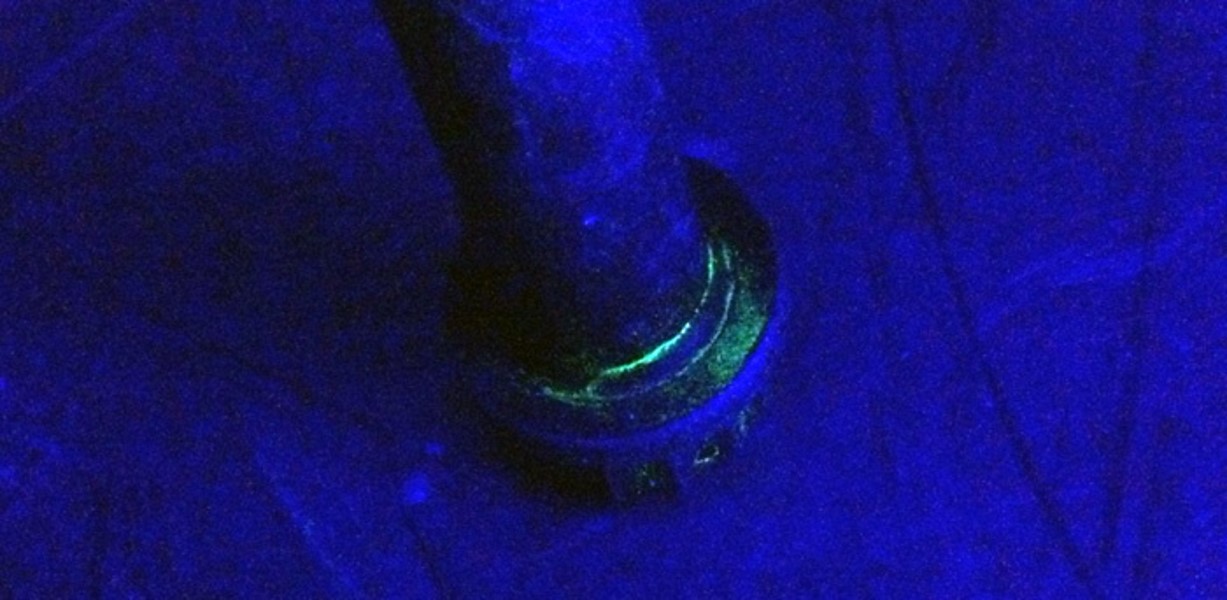

- Dye penetrant inspections – visible and fluorescent methods

- Leak detection – bubble check, mass spectrometer and ultrasonic

- Radiography – x-ray machine, radioisotope, micro-focus real-time, computed tomography

- Ultrasonic inspection – flaw, high-resolution thickness, bond integrity and bolt torque elongation

- Shearography

- Eddy current inspection – flaw detection, coating thickness and conductivity measurements

- Infrared testing (thermography) – qualitative and quantitative

- Large chamber CT

- Backscatter

- Custom optics solutions

- Practical solutions to solve difficult multidiscipline problems including tool development & COTS modification

Accomplishments

- Conducted Orbital Tube Weld inspections using Digital Radiography (DR) for Orion Exploration Flight Test-1

- Conducted Dye Penetrant (PT) and Magnetic Particle Testing (MT) of steel girder assemblies to inspect for laminations on the Space Launch System Mobile Launcher

- Conducted Computed Tomography (CT) analysis of Orion COPVs with high velocity impacts

- Performed rapid development of a

- Thermographic inspection of Shuttle wing leading edge reinforced carbon-carbon (RCC) panels in response to Columbia accident

- Shearography inspection method for external tank insulating foam