Metrology Laboratory

The Metrology Laboratory provides precision measurement and dimensional analysis of small and moderate sized parts. The Metrology Laboratory is also responsible for optical window testing, thread form verification, and surface finish determination.

Specialized Equipment/Capabilities

Precision Measurement and Dimensional Analysis:

- Brown & Sharpe Global Image 9128 Coordinate Measuring Machine (CMM)

- Contact measurement system using a touch probe-based technique to provide accurate measurements within ~0.0002”

- Micro-Vu Excel 4220 Optical Coordinate Measuring Machine (CMM)

- Non-contact measurement system to provide accurate measurements within ~0.0008”

- Mahr Contour Perthometer

- Contact measurement system used to determine surface finish accurate within ~0.0008”

- Quest Metrology Threadview Inspection System

- Vision measurement system used to determine thread form verification accurate below ~0.0001”

- Various hand tools

- Micrometers, height gauges, intrimiks, calipers, etc.

Optical Window Testing and Analysis:

Optical Windows Testing Table (sample size maximum 24 x 36”)

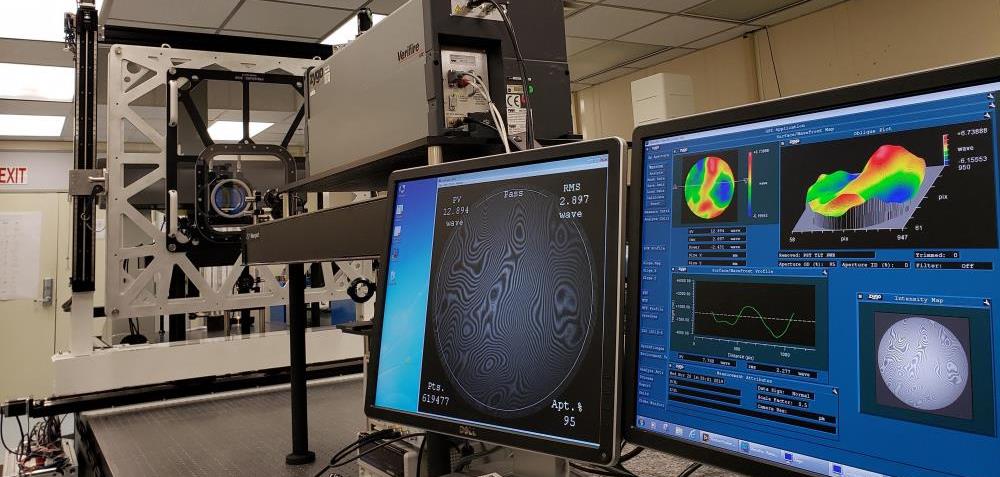

- Zygo Interferometer

- Non-contact measurement system that creates a topographical map of the surface (illustrates the surface thickness deviations) of the sample

- Haze Instrument

- Non-contact measurement system that analyzes light being dispensed throughout the sample material

- Visible Light Spectrometer (Transmission)

- Non-contact measurement system used to determine the amount of light that passes through the material using the visible light spectrometer in 5 nanometer steps (~380nm-780nm)

Full Spectrum Optical Testing (samples smaller than ~6” in diameter or length)

- PerkinElmer Spectrometer (Haze and Transmission)

- Used to test haze (contact) and transmission measurements in the UV/VIS/NIR range (180nm-3000nm)