Mechanical and Environmental Testing Laboratory (METL)

The controlled environment portion is used for both ground and payload support activities that require environmental (temperature, humidity, lighting, and CO2) control for conducting the tests. The lighting systems provide high intensities that accommodate plant growth testing. The laboratory maintains a centralized COTS Opto 22, monitoring and control system with an associated data collection and alarm notification capabilities. The software monitors conditions within the chambers, record data, and can run specific programmable scripts from the controllers. The laboratory consists of various sizes with different capabilities for lighting. Controlled environmental parameters are readily modified to support a wide range of user-defined environmental control requirements. Program customers include the Human Research Program, AES, and HEO Space Life and Physical Science. This includes the system that is known as “OMCS”, Opto 22 Monitor and Control System.

Capabilities

- A monitoring, control, alarm and data managing system

- 64 sf walk-in chamber with T8 high output fluorescent lamp canopy, temperature, RH, light period, CO2 control

- 6 sf reach-in chambers with T12 high output fluorescent lamps, temperature, RH, light period control

- sf reach-in chamber with T12 high output fluorescent lamps, temperature, RH, light period control

- 7.3 sf reach-in chamber with T8 high output fluorescent lamp canopy, temperature, RH, light period, CO2 control

- 32 sf reach-in chamber with T8 high output fluorescent lamp canopy, temperature, RH, light period, CO2 control

- 4.8 sf reach-in chamber with temperature, RH control

- 2 sf reach-in chambers with temperature, RH control

- 6 sf reach-in chamber with temperature, RH control

- 4 sf reach-in high altitude chamber with temperature, RH control

- 10 sf reach-in high altitude chamber with temperature

- 6 sf reach-in thermo-high vacuum chamber with temperature control

- 1 sf reach-in high vacuum chamber

- Drying Oven, Minus 20 freezer, Circulating Chiller, Freeze Dryer

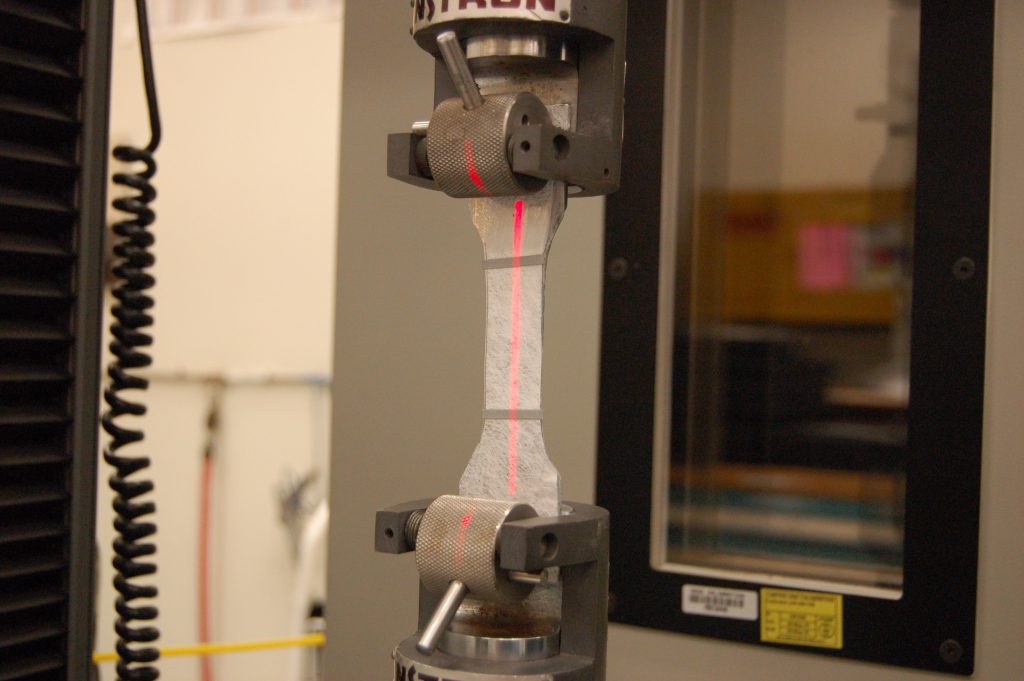

The mechanical testing and failure analysis portion of the lab performs mechanical, physical, and environmental testing of materials including tensile, compression, fatigue, altitude, humidity, temperature, flammability, electrostatic discharge, and materials compatibility along with performing failure analysis of mechanical components, pneumatic testing and simulation, dissection and disassembly/test, teardown and evaluation, providing independent failure analyses, testing, and root cause determinations of mechanical systems or components (such as valves, regulators, motors, shafts, bearings, fasteners, and pumps) used in aerospace flight hardware, ground support equipment, and related facilities. The lab also has thermal vacuum chambers, environmental chambers, and portable vacuum capabilities.

Capabilities

- Tension, compression, fatigue testing, thermal vacuum and environmental chambers

- Flammability, electrostatic discharge, hypergols, oxygen compatibility testing

- Pneumatic and hydraulic testing tables

- Dissection Lab Equipment

- Bridgeport Mill w/ AGE Trak-2 CNC; Wilton Tool Room Lathe 9” x 20”