Mechanical and Environmental Testing Laboratory (METL)

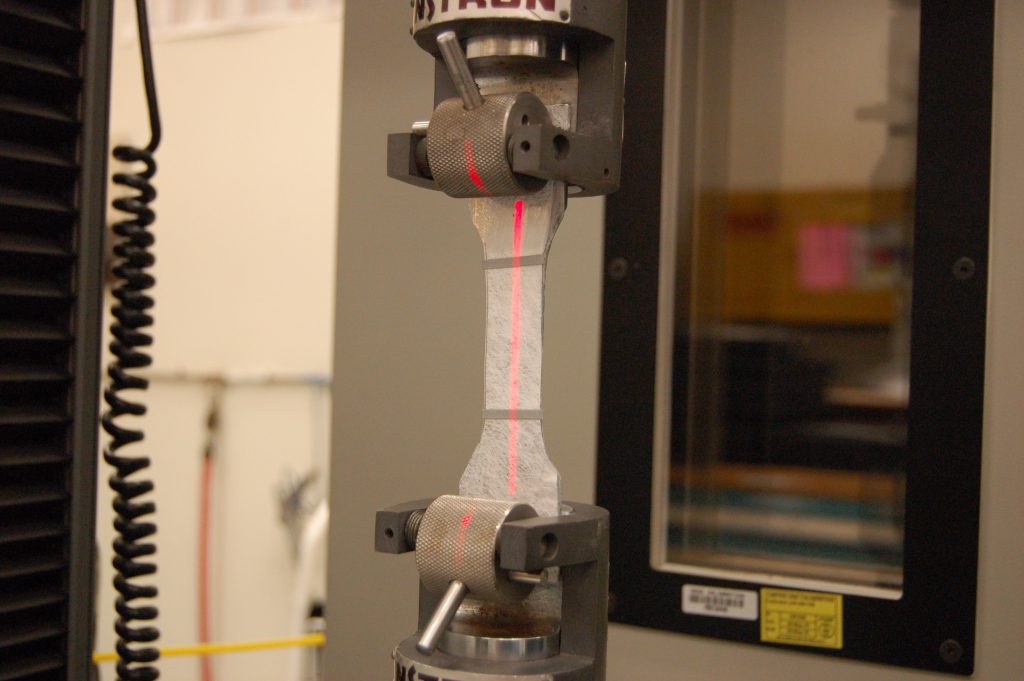

The METL is comprised of two parts: mechanical/physical materials testing and corrosion testing. The mechanical/physical materials testing portion of the lab performs mechanical, physical, and environmental testing of materials including tensile, compression, fatigue, altitude, humidity, temperature, flammability, electrostatic discharge, and materials compatibility along with performing failure analysis of mechanical components, pneumatic testing and simulation, dissection and disassembly/test, teardown and evaluation, providing independent failure analyses, testing, and root cause determinations of mechanical systems or components (such as valves, regulators, motors, shafts, bearings, fasteners, and pumps) used in aerospace flight hardware, ground support equipment, and related facilities. The lab also has thermal vacuum chambers, environmental chambers, and portable vacuum capabilities.

- Tension, compression, fatigue testing, thermal vacuum and environmental chambers

- Flammability, electrostatic discharge, hypergols, oxygen compatibility testing

- Pneumatic and hydraulic testing tables

- Dissection laboratory equipment

- Bridgeport Mill w/AGE Trak-2 Computer Numerical Control; Wilton Tool Room Lathe 9” x 20”