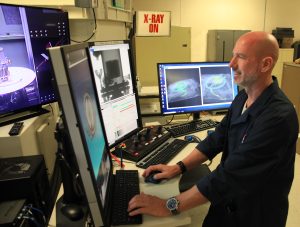

Materials Analysis Lab (MAL)

The MAL performs failure analysis of materials, mechanical components, and electrical components for all KSC programs and external customers. Set up to perform quick-turnaround anomaly investigations that occur on center, the MAL has a wide set of capabilities to evaluate failed components. Services include advanced non-destructive evaluation via real-time radiography and 3D volumetric inspection with dimensional analysis via computed tomography (DR/CT), detailed photodocumentation, digital microscopy, electron microscopy, metallurgical evaluations, weld evaluations, hardness testing, and thermal imaging. Laboratory personnel are highly skilled in fire, accident, and mishap investigations, providing independent failure analyses, testing, and root cause determinations of electrical or mechanical systems or components such as valves, regulators, motors, shafts, bearings, fasteners, and pumps used in aerospace flight hardware, ground support equipment, and related facilities.

- Digital radiography/Computed tomography (DR/CT)

- Electrical testing: analog, digital & mixed signal testing equipment; high-voltage facility power; high-frequency electrical & DC power system testing

- Thermal imaging cameras

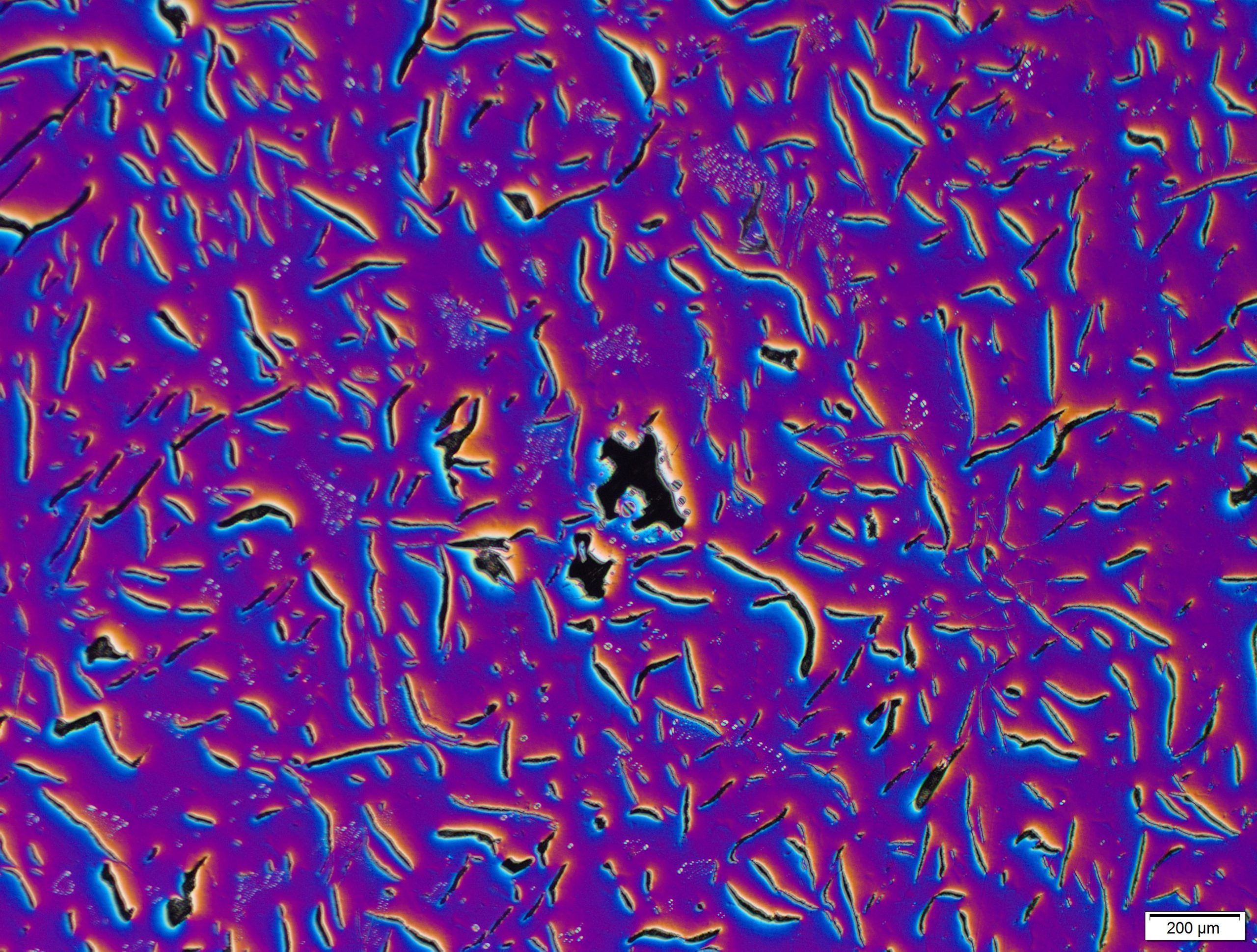

- High magnification digital capture microscopes, stereomicroscopes, metallographs, profilometer, confocal microscope

- Hardness testers (including portable and micro)

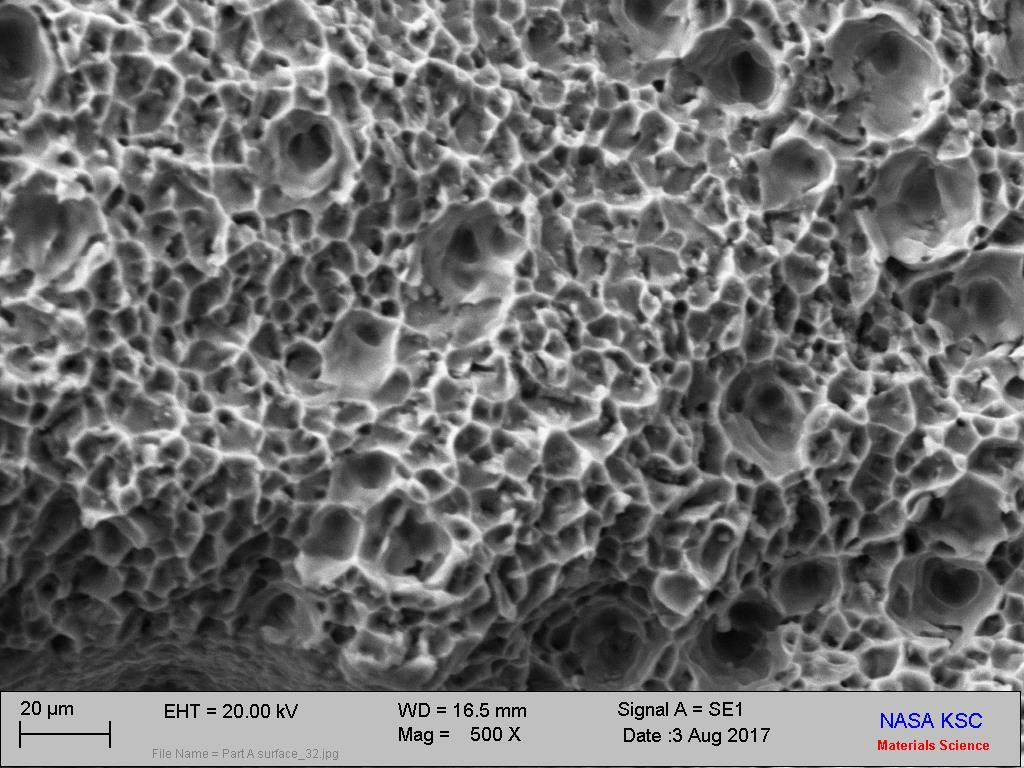

- Environmental Scanning Electron Microscope (SEM) with a Focused Ion Beam (FIB), Energy Dispersive Spectroscopy (EDS), and Electron Backscatter Diffraction (EBSD)

- X-Ray Photoelectron Spectrometer (XPS)

- Thermogravimetric Analyzer (TGA) with Gas Chromatograph (GC) and Infrared Spectrometer (FTIR),

- Differential Scanning Calorimetry (DSC)

- Thermomechanical Analyzer (TMA)

- Dynamic Mechanical Analyzer (DMA)

- Simultaneous Thermal Analyzer DSC/TGA (SDT)

Capabilities

- Stereomicroscopes

- Metallographs

- Profilometer

- Confocal microscope

- Hardness testers (including portable and micro)

- Environmental Scanning Electron Microscope (SEM) with a Focused Ion Beam (FIB) Energy Dispersive Spectroscopy (EDS), and Electron Backscatter Difraction (EBSD)

- X-Ray Photoelectorn Spectrometer (XPS)

- Thermogravimetric Analyzer (TGA) with Gas Chromatograph (GC) and Infrared Spectrometer (FTIR)

- Differential Scanning Calorimetry (DSC)

- Thermomechanical Analyzer (TMA)

- Dynamic Mechanical Analyzer (DMA)

- Simultaneous Thermal Analyzer DSC/TGA (SDT)