Electrical Development Laboratory (EDL)

The EDL is a consolidation of multiple existing laboratories specifically established for Ground Support Equipment (GSE), launch structures, and flight projects/programs based out of KSC. The laboratory provides electrical/electronic design, development, fabrication, testing, integration, qualification, and sustaining capabilities based on NASA program requirements in the areas of transducers and sensors, instrumentation and data acquisition, electronics, control systems, power, embedded systems, and range technologies. The laboratory integrates the following capabilities:

Advanced Electronics & Technology Development Capability (AETDC)

The AETDC performs design and sustaining engineering for circuit boards, as well as board- and assembly-level development, prototyping, and evaluation for electronic and electrical designs or equipment.

Specialized Equipment

- Alternating current/direct current (AC/DC) power supplies

- Counters

- Data acquisition systems

- Decade resistance and capacitance boxes

- Electronic load banks

- Frequency response analyzers

- Printed circuit board milling machine

- High-speed digital oscilloscopes

- High-speed wideband serial data analyzer

- Programmable pulse generator

- Time domain reflectometer (TDR)

Controls Development Capability (CDC)

The CDC supports the development, testing, and sustaining engineering of programmable logic controller (PLC)-based instrumentation for process monitoring and control of GSE and facilities. This also includes the networking capabilities for linking multiple subsystems to the command and control systems.

Specialized Equipment

- Programmable logic controllers (PLCs)

- Uninterruptable power supplies (UPSs)

- Fiber optic test equipment

- Human machine interfaces (HMIs)

- Development workstations

- User authentication

- Development and configuration management servers

- Ethernet network switches

- Network analyzers

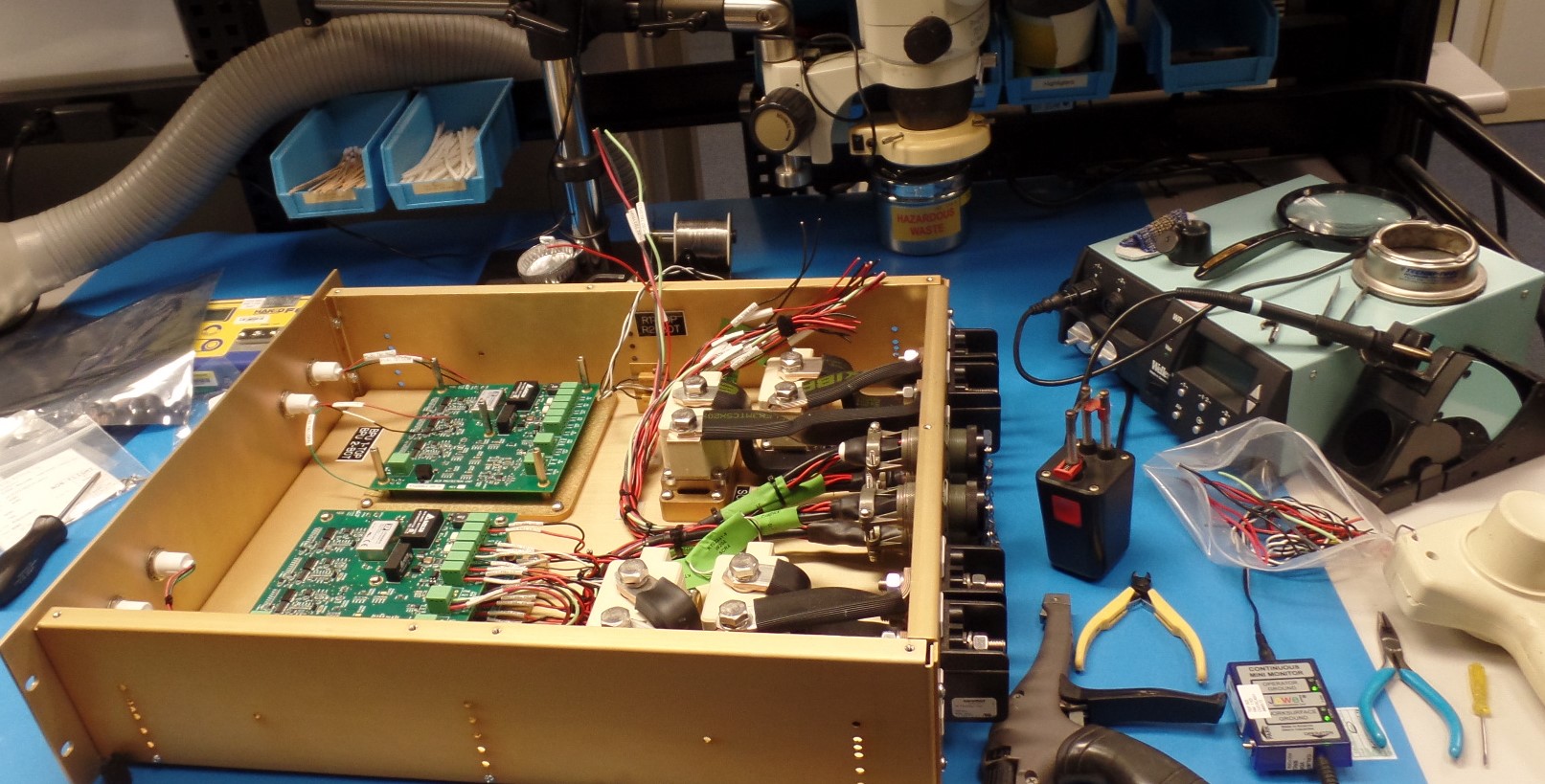

Electronics Development & Test Capability (EDTC)

The EDTC performs circuit board manufacturing; test and rework activities; board- and assembly-level development; and prototyping and evaluation for electronic and electrical designs or equipment.

Specialized Equipment

- Surface-mount soldering

- Ball grid array (BGA) soldering/rework

- Video microscope

- Electrostatic discharge (ESD) assembly stations

- Reflow oven

Electrical Hardware Support Capability (EHSC)

The EDL maintains a fabrication and machining workshop that supports all the engineering functions for part prototyping and/or modification.

Specialized Equipment

- Breaks, Crimp tools, Cutting tools, Drill motors, electric or pneumatic, Drill presses, Files, hands (any type), Flaring tools, Grinding and lapping tools, Insertion/removal tools, for connector pins or sockets, Inspection/measurement tooling, Mills, Notchers, Pipe and tube bending tools, Pliers, diagonal cutting/needle nose/channel lock/locking, Punches, Rivet guns and threaded insert tools, Sanders, hand block or electric, and Saws

Fabrication, Assembly & Test Capability (FAT)

The FAT capability performs fabrication, assembly, and test of electrical and electronic equipment for use in ground support and facility systems. The primary focus of the capability is racks and electrical enclosures, including internal wiring, electrical equipment installation, and checkout.

Tools/ Equipment

- Mills

- Notchers

- Drill motors (electric or pneumatic)

- Rivet guns

- Pull testers

- Rotary engraving machine

- Milliohm meters

- Torque tools

- Wire wrap tools

- Soldering tools

- Electrostatic discharge (ESD) workstation

Ground Systems Health & Diagnostic Capability (GSHD)

The GSHD capability conducts activities that include: Design, Development, Test, and Engineering (DDT&E) of software/hardware; prototyping of software/hardware. Activities are primarily in support of Prognostics, Anomaly Detection and Health Management (HM) Technologies.

Specialized Equipment

- Prognostics, Anomaly Detection, Functional Fault Modeling and Health Management development tools. Modeling and Simulation capabilities.

Hazard & Gas Capability (HGDC)

The HGDC capability performs the evaluation, characterization, qualification, and sustaining engineering of instrumentation assemblies, subassemblies, and components related to hazardous gas leak detection. It also fabricates instrumentation including prototypes, test support equipment, facility equipment, and ground support equipment for hazardous gas leak detection.

Specialized Equipment

- Residual gas analyzers (RGA)

- Vacuum pumps

- Turbo pumps

- Flow controllers

- Flow meters

- Valves

- Pressure sensor/transducers

- Gas delivery system

- Helium leak detectors

- Tubing benders

- Drill press

Power Systems Development Capability (PSDC)

The PSDC supports the design, development, and sustaining engineering of GSE power systems, including equipment rack/subsystem power, alternating current/direct current (AC/DC) power systems, launch vehicle special power, and battery-based power systems.

Specialized Equipment

- Frequency response analyzers

- Electronic load banks

- Data acquisition systems

- Battery simulators

- Battery management systems

- Digital multimeters (DMMs)

- Digital oscilloscopes

- Power meters

- Decade boxes

- AC/DC power supplies

Range Development Capability (RDC)

The RDC performs Range research and development; this can include analysis, simulations, and testing.

Specialized Equipment

- Frequency response analyzers, Inductance, Capacitance and Resistance (LCR) meters, Multimeters, Milliohmmeters, Network analyzers, Oscilloscopes, Power meters, Power supplies, Signal generators, Spectrum analyzers, Switching devices.

Sensor Data Acquisition Subsystem Capability (SDAS)

The SDAS is a distributed, stand-alone data acquisition subsystem that supports stacking, rollout, and launch operations. It monitors and records temperature, pressure, flow rate, acoustic, strain, environmental and special measurements. The SDAS is specifically designed to support highspeed engineering data gathering as well as local and remote display and data storage. The SDAS capability performs evaluations of data acquisition equipment and cables in various configurations to support this subsystem.

Specialized Equipment

- AC/DC power supplies, Counters, Data acquisition systems, Decade resistance and capacitance boxes, Electronic load banks, Frequency response analyzers

Sensors & Transducers Development (TDC) and Electromagnetic Interference (EMI) Capabilities

The TDC capability provides engineering and sustaining engineering support for KSC transducers and signal conditioners including design, qualification, specification, testing, and troubleshooting. This includes development and maintenance of transducer specifications to ensure accuracy, reliability, and interchangeability of sensors used in ground support equipment (GSE) systems at KSC. The TDC capability also maintains a remote test site for hydrogen sensor and flame detector testing. The EMI Capability provides pre-compliance EMI/Electromagnetic compatibility (EMC) evaluation and analysis support. The EMI capability provides design recommendations, component/system test, and modifications for MIL-STD-461 EMI compliance.

Equipment for Sensors and Transducers Development Capability

- Humidity test equipment

- Pressure test equipment (Pneumatic and Hydraulic)

- Portable pressure standards

- Temperature test equipment (including Cryogenic)

- Temperature standard

- Thermocouple simulators

- Load Cell test equipment

- Flow test equipment

- Environmental chambers

- Counters

- DC power supplies

- Precision sources

- Bench calibrators

- Data acquisition equipment

Specialized Equipment for EMI Testing

- Antennas

- Attenuators and terminators

- Calibration fixtures

- Current probes

- Directional couplers

- Electric field probes and monitors

- Near-field probes

- Network analyzers

- Oscilloscopes

- Power meters

- RF amplifiers

- Semi-anechoic chambers

- Signal generators

- Spectrum analyzers

Weather Capability (WX)

The WX capability performs various activities dedicated to the development and sustaining of weather instrumentation hardware and software. These activities are performed in support of systems deployed at KSC, at lightning research facilities, and at outside-customers’ facilities.

Specialized Equipment

- Transient recorders

- Fast-digitizing data acquisition recorders

- High-speed cameras

- Magnetic and electric field sensors