Corrosion Engineering Lab

*Please visit KSC’s Corrosion Engineering Laboratory website

The Corrosion Engineering Laboratory a subset of the Mechanical and Environmental Testing Laboratory at Kennedy Space Center is a network of people, equipment, and facilities that provide engineering services and technical innovations in all areas of corrosion for NASA and external customers. KSC has also developed some corrosion technologies that are available for licensing.

Kennedy Space Center’s launch facilities are located within 1000 feet of the Atlantic Ocean. Salt from the ocean combined with the heavy lift launch vehicles’ acidic rocket exhaust make corrosion protection a high priority. For these reasons, KSC maintains state-of-the-art corrosion testing capabilities. Over the years, numerous material failures at KSC have been attributed to various forms of corrosion (atmospheric corrosion, stress corrosion cracking, pitting corrosion, crevice corrosion, intergranular corrosion, hydrogen embrittlement, and corrosion fatigue). Materials testing and applied research is performed by engineers and technicians at the Corrosion Engineering Laboratory to identify solutions to resolve many of these material failure concerns.

The NASA KSC Corrosion Engineering Laboratory consists of a Beachside Atmospheric Corrosion Test Site, a Coatings Application Booth, and an Indoor Corrosion Laboratory. In addition, the Corrosion Engineering Laboratory works within the larger NASA Engineering Directorate to include other capabilities for performing both chemical and physical analysis on coatings and materials, non-destructive evaluation (NDE) methods, and testing, such as tensile, shock, and vibration.

Primary Capabilities:

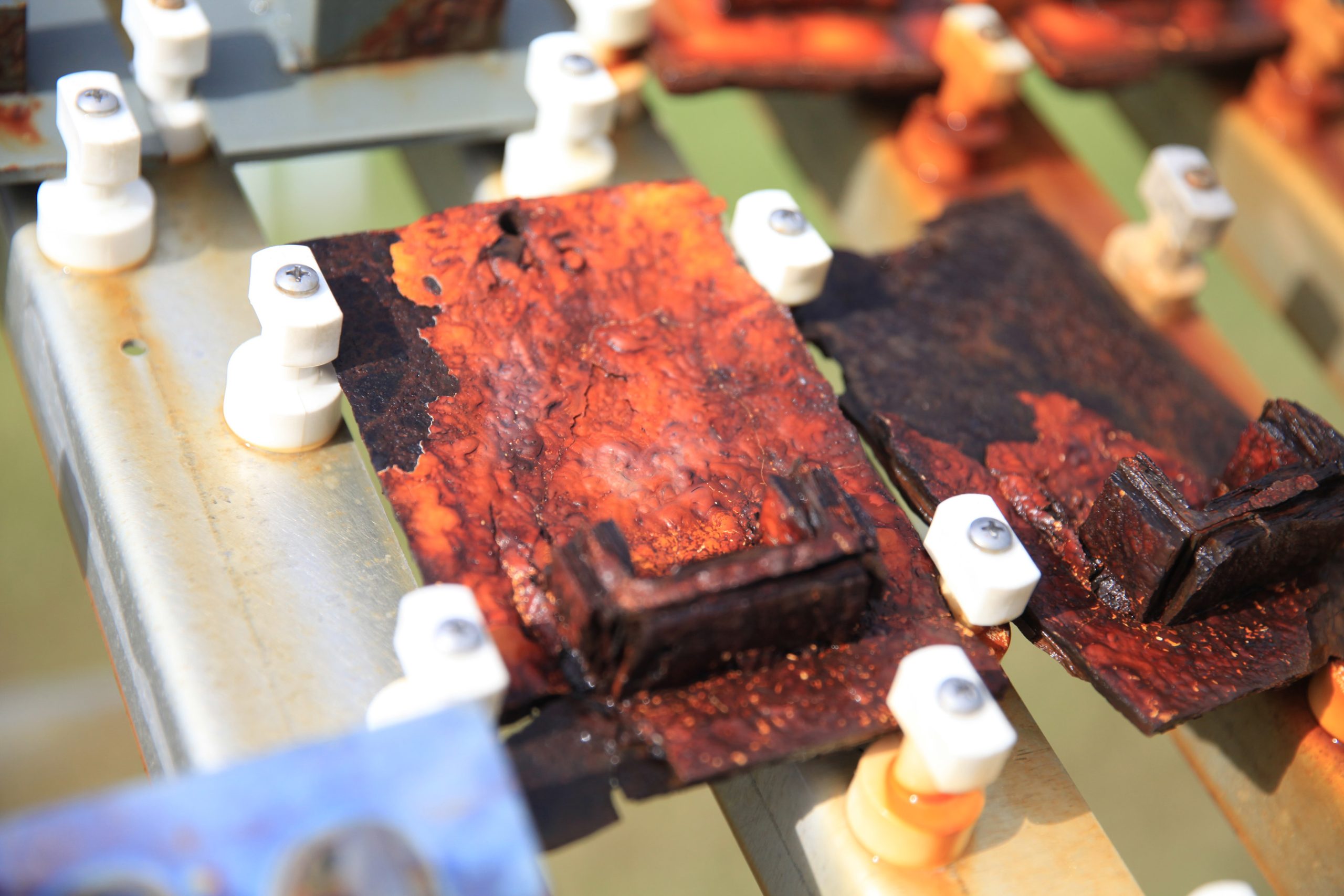

Beachside Atmospheric Exposure

- 900 linear feet of beach front space along the Atlantic Ocean, documented as having higher atmospheric corrosion rates than other known test sites in the United States

- Over 50 years of information on the long-term performance of many different types of materials

- Accommodates small test panels and a variety of other odd shapes and sized components for fully exposed and partially covered exposures

- Seawater flow tanks with full/alternating immersion and seawater spray capabilities

- Southern-facing atmospheric test racks for prolonged UV studies

- Full weather station

- Corrosion rate and chloride concentration measured seasonally

- Sample preparation, electrochemistry, analysis, and machine shop on site

Accelerated Corrosion and Physical Testing

- Continuous and cyclic salt fog chambers

- Accelerated, temperature, humidity, and UV testing

- Coating adhesion, thickness, hardness, color, and gloss measurements

- Surface emissivity and absorptivity

The Corrosion Engineering Laboratory is a multiuser facility that serves NASA Centers, various DoD and Government Agencies, private companies, and educational institutions. The KSC Beachside Atmospheric Exposure Test Site is unique within the government, making it a valuable resource that is also available to customers outside NASA.