Payload Processing

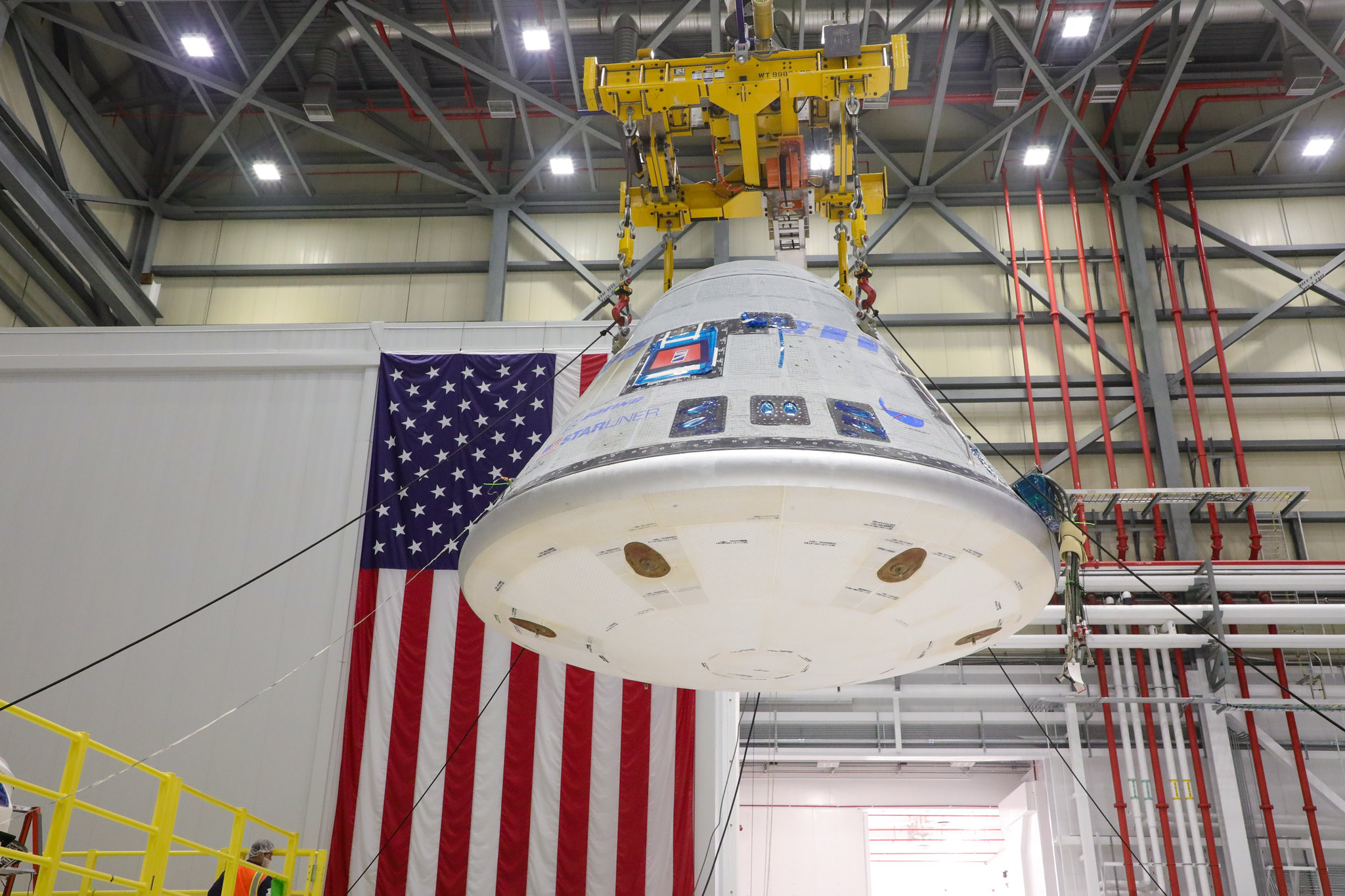

The Starliner crew module is hoisted in Boeing’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida on Jan. 19, 2023, before being mated to a new service module for NASA’s Boeing Crew Flight Test.

Kennedy Space Center’s (KSC) Payload Processing teams have decades of experience supporting NASA and commercial partners in all aspects of preparing and launching payloads into space. In addition to a wide array of expertise, the center offers a variety of equipment and facilities to help prepare, process and support payloads of nearly all sizes and types, including life science and biological payloads. The level of support can be tailored to fit the needs of each partner.

Capabilities

Payload Processing support includes:

- Assistance with launch site policies, planning, scheduling, and development of safety and emergency preparedness plans

- Assistance on the repair of flight and ground equipment (mechanical, electrical power, command and data handling, avionics, and fluids systems)

- Non-destructive evaluation and inspection

- Material Engineering and Analysis (chemical sampling & analysis, material testing, contamination/cleanliness control)

- Hazardous waste handling (waste streams generated by payload processing)

- Payload hardware designs evaluation for impacts to KSC facilities and equipment

- Assessment of ground operations and maintenance hazards in order to ensure safety of KSC personnel and property

- High fidelity simulation and visualization (two dimensional, and three dimensional modeling) to address flight and ground hardware access and clearance concerns during processing

- Control and handling of ordnance

- Logistics support (transportation, shipping and receiving, storage, loan pool equipment including tools, headsets, and clean-room garments)

- Flight hardware Integration support includes: fit checks, assembly and integration; handling; alignment checks; weight and Center of Gravity (CG) determination; servicing; maintenance; testing; and closeouts

Fluids and Gasses Servicing: high pressure gas servicing (hydrogen, oxygen, nitrogen, helium) and hazardous fluids servicing, with experience in the servicing of NH3; N2H4; MMH; UDMH; N2O4; JP8/RP1; H2O2; LN2; LO2; and LH2. Internal Thermal Control System fluid servicing of ISS internal payloads.

Payload Testing: The KSC team can support customers with a wide variety of tests that, based on decades of experience, are necessary for mission success. These tests include:

- Electromagnetic Compatibility

- Leak Test

- Post Delivery Verification Test

- Interface Verification Test

- End-to-End test

- Flight Load Verification

- Launch Simulations

- Mission Sequence Test

- Integrated Compatibility Test

- Subsystems Test

- Spin Test

Payload Launch Operations: The KSC team can provide a variety of support services for payload launch operations. Capabilities include, but are not limited to:

- Developing launch countdown procedures

- Loading and verifying launch console applications software and displays

- Documenting payload Launch Commit Criteria operations

- Staffing payload consoles during payload pad and launch countdown activities

- Planning and providing contingency procedures for launch delays, scrub turnarounds, and launch termination scenarios.

Accomplishments

- SAGE III (Stratospheric Aerosol and Gas Experiment), launching on SpaceX-10 — Installed Passive Flight Release Attachment Mechanism (PFRAM) and Axial Compliance Kit integration for the Nadir Viewing Platform (NVP) component; Performed alignment verifications

- DSCOVR (Deep Space Climate Observatory) satellite, launched in February 2015 — Performed hazardous hypergolic fueling servicing

- MAVEN (Mars Atmosphere and Volatile EvolutioN), launched November 2013 – supported offload and transportation, launch site processing, hurricane contingency operations, and fueling

- AMS-02 (Alpha Magnetic Spectrometer), launched May 2011 – supported offload and transportation, integration, cryogenic fuel servicing, weight and CG, power quality test, orbiter interface verification test, terminal countdown demonstration test, end to end test, pad closeouts, and SFHe top-off

- Supported SpaceX missions by processing and delivering International Space Station (ISS) payloads and Orbital Replacement Units (ORU) to the Payload Processing Facility (PPF)

– RapidScat, launched September 2014 – Installed Passive Flight Release Attachment Mechanism (PFRAM), performed alignment verifications at Jet Propulsion Laboratory (JPL), supported JPL on performing end-to-end test, and provided host role support while at KSC

– GLACIER (General Laboratory Active Cryogenic ISS Experiment Refrigerator) and Merlin (Microgravity Experiment Research Locker Incubator), both ISS payloads, launched April 2014 – Performed Internal Thermal Control System (ITCS) fluid servicing, and performed weight and CG

– Serviced ISS Audio Terminal Unit ORU water lines (fill, leak check, circulate, sanitize, and sample) in support of Orbital -3 mission.

– Serviced ISS Pre-Treat Urine Hose (pre-treat solution, fill, and sample) in support of SpaceX-4 mission.

– Flight filled ISS Oxygen and Nitrogen Recharge Tank Assemblies in support of various SpaceX missions

- OA-4 and OA-6 ISS cargo missions – Supported Orbital/ATK processing team by providing:

– Clean room facility space in the SSPF

– Host support in the areas of cab crane use, fluids and gas services, lab cleaning equipment and other heavy equipment services