Coating, Application, and Testing

The NASA KSC Corrosion Engineering Laboratory has the facilities, equipment, and experience to fully prepare materials for corrosion or other materials-related testing. Because NASA tests and qualifies its own coatings, the coatings must be applied our facility as well in order to maintain complete objectivity over test results. The lab also has access to a large variety of machining and preparation facilities outside of the Corrosion Engineering Laboratory but still within the confines of NASA KSC for specialty needs.

In-house surface preparation capabilities include:

Substrate selection and machining

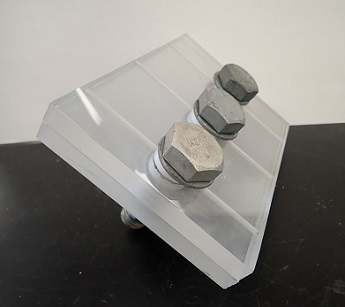

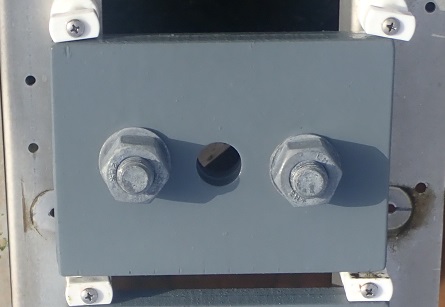

The KSC Corrosion Engineering Laboratory stocks a variety of common structural and aerospace-related metal samples for the most common testing. Panels are selected based on their intended end use application and configuration. NASA KSC most commonly conducts tests using flat panels, panels with welded c-channels, fastener configurations, bolt configurations, stress-corrosion cracking, and dissimilar metal configurations. Often NASA’s test needs require atypical configurations, so flexibility for sample design and modification is important.

Surface Preperations

The Corrosion Engineering Laboratory has a variety of surface preparation options including grit blasting and polishing. KSC has laboratory and full production scale facilities for degreasing, etching, and passivating metals.

Coatings application

The Corrosion Engineering Laboratory has a paint booth that is used to apply coatings in-house in a controlled environment. Containment tents are also available to apply coatings to larger structures in the field at the Beachside Atmospheric Corrosion Test Site. A variety of coatings application methods for both inorganic and organic-based coatings and Corrosion Preventive Compounds (CPCs) are able to be applied via spraying methods, such as airless, gravity fed or pressure pot conventional, HVLP. KSC has laboratory and full production scale facilities for applying conversion coatings and other pretreatments.

Sample Test Preparation

The Corrosion Engineering Laboratory has the ability to further prepare coated samples for testing such as scribing via hand scribing or with an auto-scriber tool.