Physical and Chemical Testing

The Corrosion Engineering Laboratory and the other laboratories across the Kennedy Space Center have the facilities, equipment, and experienced personnel to perform a large variety of materials-related testing beyond corrosion testing. Often corrosion testing is performed in tandem with mechanical and chemical testing based on the larger program needs. The Corrosion Engineering Laboratory can act as a single source to provide test results beyond corrosion results should other test methods be needed.

Testing provided directly by the Corrosion Engineering Laboratory in tandem with corrosion testing:

- Coating testing: thickness, hardness, pull or peel strength adhesion, color, gloss, solar emissivity, and reflectivity.

- Stress corrosion testing: Bent beam, U-bend, C-ring, and tensile type specimens in accelerated or long-term atmospheric test environments.

- Tensile testing: Fatigue, stress, compression, lap shear, adhesion.

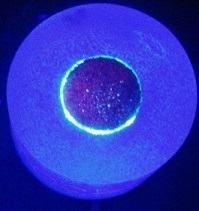

- Chemical interface characteristics and degradation: FT-IR, SEM, XPS, and surface hydrophobicity via contact angle.

Testing provided indirectly by the Corrosion Engineering Laboratory if in tandem with corrosion testing:

- Non-Destructive Evaluation (NDE): CT scanning, X-ray, dye penetrant, ultrasound, and terahertz.

- Specialty Testing: Vibration, vacuum, electrostatic, electrical, conductivity.